D2DB-Image Explorer

There is growing interest in high resolution images and a growing investment in the tools that generate those images. As feature sizes shrink well past the limits of optical resolution, it is not unusual for advanced fabs to employ twenty or more SEM tools and ten or more E-Beam inspection tools. The images they generate are vital to the understanding of yield limiting factors.

Unfortunately, these images are significantly underutilized. SEM Review images, for example, are assigned a class code either by SEM ADC software or by a human operator. But these images contain a lot more information that is neither extracted nor used. The rich information content of images is reduced to a mere class code.

D2DB-Image Explorer is a set of functions (a toolkit) that allow customers to extract the rich information content of images and integrate that information into their own custom workflows (or batch jobs).

Two light-weight GUIs are also provided, allowing users to experiment with the various features and settings, and to review results.

D2DB-Image Explorer is an off-tool and vendor-neutral solution, which means it can be installed on the user’s hardware to process images from any SEM and E-Beam tool. It allows users to maximize their return on investment from high resolution imaging tools, and to build unique solutions for their unique problems.

(Note that successful image processing depends on the pixel size, number of pixels (FOV), and overall image quality. Image Explorer compensates for many image artifacts, but it cannot compensate for severe image quality issues.)

Unfortunately, these images are significantly underutilized. SEM Review images, for example, are assigned a class code either by SEM ADC software or by a human operator. But these images contain a lot more information that is neither extracted nor used. The rich information content of images is reduced to a mere class code.

D2DB-Image Explorer is a set of functions (a toolkit) that allow customers to extract the rich information content of images and integrate that information into their own custom workflows (or batch jobs).

Two light-weight GUIs are also provided, allowing users to experiment with the various features and settings, and to review results.

D2DB-Image Explorer is an off-tool and vendor-neutral solution, which means it can be installed on the user’s hardware to process images from any SEM and E-Beam tool. It allows users to maximize their return on investment from high resolution imaging tools, and to build unique solutions for their unique problems.

(Note that successful image processing depends on the pixel size, number of pixels (FOV), and overall image quality. Image Explorer compensates for many image artifacts, but it cannot compensate for severe image quality issues.)

Click to Compare

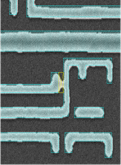

Annotation and Markup Removal

Text and markers on the image (e.g. micron marker) can impede contour extraction. These annotations can be removed using an advanced algorithm that removes these objects and reconstructs their backgrounds.

Click to Compare

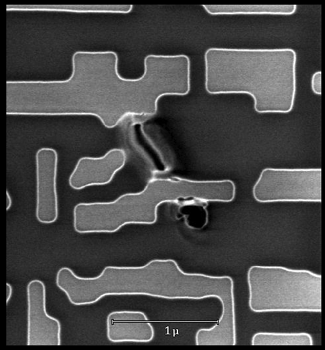

Contour Extraction

Image quality varies widely from tool to tool, layer to layer, wafer to wafer. This requires re-tuning of the contour extraction parameters on a regular basis. However, D2DB-Image Explorer provides Automatic Parameter Setup that adjusts all of the contour extraction parameters individually for each image. This mitigates the need for human intervention and promotes use in production environments.

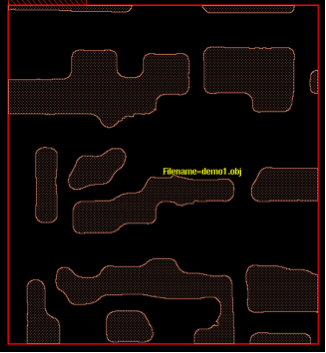

Contour Alignment

This feature overlays and aligns the contour to the design to eliminate any offset or coordinate measurement error from inspection defects. Despite line edge roughness and corner rounding inherent in every contour, the contour is aligned precisely to the design. (Note that regions with highly repetitive pattern present a challenge because the contour could be aligned to any of the repeated patterns. There are options for dealing with this type of ambiguity.)

Contour Search

Whereas contour alignment operates within a relatively small area of the design and makes a priori assumptions about the rotation of the contour, Contour Search is designed to operate on the full chip or any subsection without making any assumptions. It will find all matching locations, including rotated and flipped orientations.

Defect Detection

Once a contour has been aligned to its design reference, it can be checked for the presence of any of the following types of defects:

• Hard Open (or break) or Partial Open (necking).

• Hard Short (or bridge) or Partial Short.

• Line End Pullback with and without via coverage check.

• Hard Open (or break) or Partial Open (necking).

• Hard Short (or bridge) or Partial Short.

• Line End Pullback with and without via coverage check.

Main Benefits:

- Set of Linux functions that provide leading-edge image processing capabilities.

- Customers can embed these capabilities into their own automation workflows.

- Vendor-neutral: D2DB-Image Explorer works with images from multiple SEM and E-Beam tool brands.

Main Features:

- Annotation and Markup Removal to clean images.

- Contour Extraction with Automatic or Manual Parameter Setup.

- Contour Alignment for offset correction (aligning contour to design within a small offset distance to compensate for inspection tool coordinate error).

- Contour Search to search the entire design or any region of the design for all occurrences of the contour.

- Defect Detection to find opens, partial-opens (necking), shorts, partial shorts, and line-end pullbacks.

In addition, D2DB-Image Explorer comes with 2 light-weight GUIs to more easily experiment with the various features and settings, and to review results.

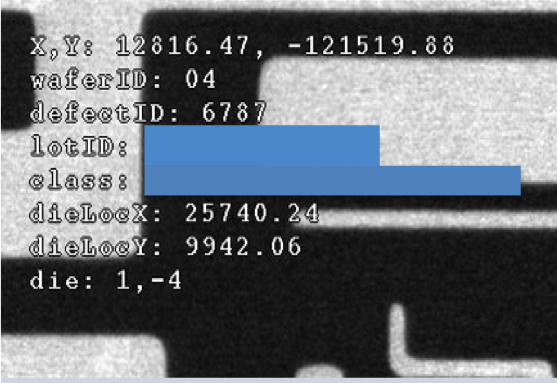

Design files (GDS / OASIS) have been used successfully in the fab for a decade, but the design file alone is not sufficient to pinpoint the location of the defect on the design. Defect coordinates reported by inspection tools contain measurement or coordinate error that ranges anywhere from 100+ nanometers to 8+ microns.

With feature sizes well below 28nm, a coordinate error of 100+ nm is excessive, and it imposes significant restrictions on the types of use cases that can be achieved.

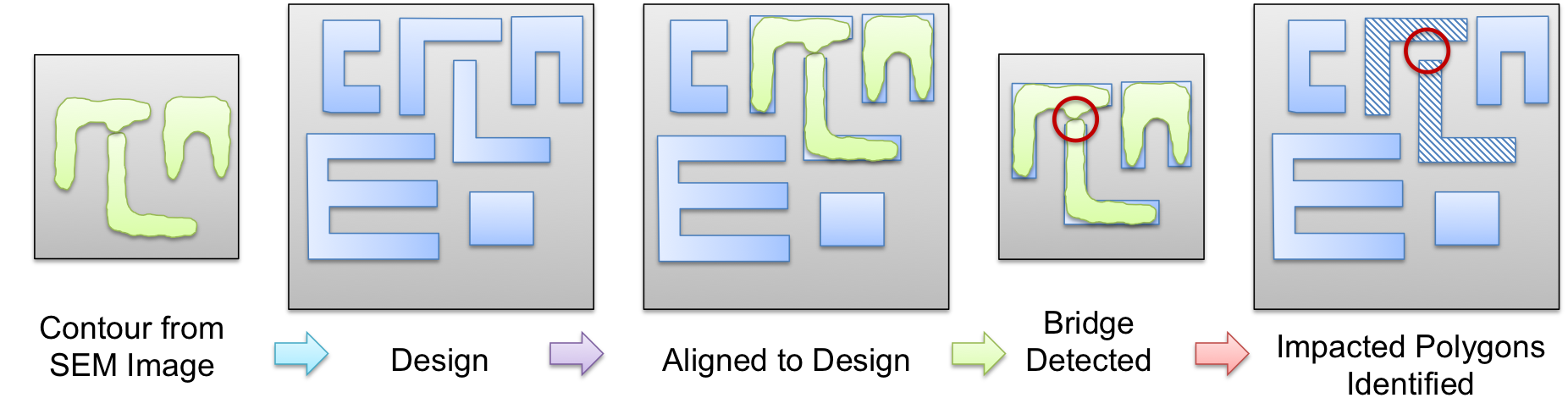

But integrating high resolution images with the design allows us to pinpoint the defect on the design and thus identify the actual impacted polygons, as shown in the figure above.

Once the actual impacted polygons have been identified, a number of new possibilities open up!

With feature sizes well below 28nm, a coordinate error of 100+ nm is excessive, and it imposes significant restrictions on the types of use cases that can be achieved.

But integrating high resolution images with the design allows us to pinpoint the defect on the design and thus identify the actual impacted polygons, as shown in the figure above.

Once the actual impacted polygons have been identified, a number of new possibilities open up!

Technical Requirements

The minimum system requirements are listed below:

Memory and hard drive requirements can vary substantially from customer to customer. Customers who expect to store large quantities of images on the server should allocate appropriate hard drive capacity. Customers who expect to process large numbers of images should allocate additional physical memory. Anchor Semiconductor will help each customer with the appropriate sizing of their hardware.

- Linux 2.6 or later, 64-bit, x86 based processor.

- 16 or more physical cores.

- 128 GB or more physical memory.

- 2 TB or more available hard drive capacity.

Memory and hard drive requirements can vary substantially from customer to customer. Customers who expect to store large quantities of images on the server should allocate appropriate hard drive capacity. Customers who expect to process large numbers of images should allocate additional physical memory. Anchor Semiconductor will help each customer with the appropriate sizing of their hardware.