PCML: Pattern Centric Machine Learning

Each layer of interest in the CAD Layout is decomposed systematically into a collection of unique constituent patterns of a specified maximum size. A poly layer, for instance, will be fully decomposed into its unique constituent patterns.

Decomposition is performed using a set of parametric search rules, which means that only patterns of interest are extracted. This eliminates don’t care patterns that would otherwise burden the database with too many nuisance patterns. When a layer is fully decomposed into its constituent patterns of interest, the result is an abbreviated representation of the layer. We call this the Design Decomposition Database.

Parametric search rules can specify both generic line space and line width patterns, or highly specific, but parametrized patterns. An example of a specific but parametrized pattern is a tip-to-line. There can be many variations of tip-to-line depending on the (a) gap between tip and line, (b) width of the tip, (c) width of the line, (d) run length of the tip, (e) run length of the line, etc. All of these [items (a) through (e)] are parameters of the specific pattern known as tip-to-line.

Parametric rules allow us to locate all variations of tip-to-line based on flexible constraints applied to all parameters (a) through (e). Creating such a rule is both intuitive and efficient by using the Parametric Rule Editor.

Decomposition is performed using a set of parametric search rules, which means that only patterns of interest are extracted. This eliminates don’t care patterns that would otherwise burden the database with too many nuisance patterns. When a layer is fully decomposed into its constituent patterns of interest, the result is an abbreviated representation of the layer. We call this the Design Decomposition Database.

Parametric search rules can specify both generic line space and line width patterns, or highly specific, but parametrized patterns. An example of a specific but parametrized pattern is a tip-to-line. There can be many variations of tip-to-line depending on the (a) gap between tip and line, (b) width of the tip, (c) width of the line, (d) run length of the tip, (e) run length of the line, etc. All of these [items (a) through (e)] are parameters of the specific pattern known as tip-to-line.

Parametric rules allow us to locate all variations of tip-to-line based on flexible constraints applied to all parameters (a) through (e). Creating such a rule is both intuitive and efficient by using the Parametric Rule Editor.

Pattern Centric Machine Learning

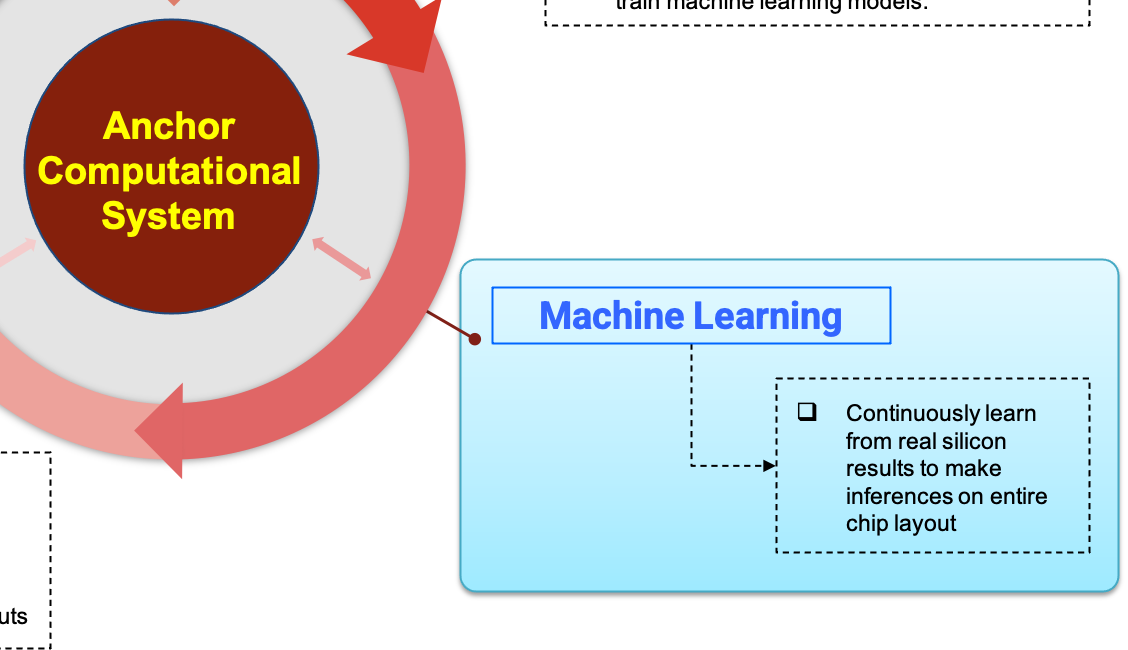

Pattern Centric Machine Learning bridges the Printed Pattern Database and the Design Decomposition Database to enable entirely new opportunities for yield learning and process optimization.

Because SEM review is a time consuming operation, only a relatively small number of images are captured on each inspected wafer. This does not cover all of the pattern variety that exists in the Design Decomposition Database, which means there is no direct empirical data for most of the patterns in that database, and hence we are somewhat handicapped in our ability to assess their process risk.

But machine learning provides a next-best solution.

Recent advancements in machine learning algorithms allow a computer to build an inference or predictive model itself using appropriate training data. Training data consists of numerous and diverse examples of inputs and their real-world outputs. The Printed Pattern Database is an ideal repository of labeled training data because it contains numerous examples of the reference pattern and the printed pattern. Deviations between the reference and printed pattern are used to label each training set. If the deviation is insignificant, the pair of reference (input) and printed (output) patterns are labeled as an example of a 'good' pattern. Conversely, if the deviation is significant, the pair of reference and printed patterns is labeled as an example of a 'bad' pattern.

The Printed Pattern Database therefore provides an automatically labeled set of training data for use by supervised machine learning algorithms.

Moreover, new SEM images that are continuously being captured by the fab are also being added to the Printed Pattern Database. This dynamic environment allows the machine learning system to learn continuously and therefore improve its prediction accuracy. As the accuracy of the machine improves over time, the system moves closer to an expert system.

Because SEM review is a time consuming operation, only a relatively small number of images are captured on each inspected wafer. This does not cover all of the pattern variety that exists in the Design Decomposition Database, which means there is no direct empirical data for most of the patterns in that database, and hence we are somewhat handicapped in our ability to assess their process risk.

But machine learning provides a next-best solution.

Recent advancements in machine learning algorithms allow a computer to build an inference or predictive model itself using appropriate training data. Training data consists of numerous and diverse examples of inputs and their real-world outputs. The Printed Pattern Database is an ideal repository of labeled training data because it contains numerous examples of the reference pattern and the printed pattern. Deviations between the reference and printed pattern are used to label each training set. If the deviation is insignificant, the pair of reference (input) and printed (output) patterns are labeled as an example of a 'good' pattern. Conversely, if the deviation is significant, the pair of reference and printed patterns is labeled as an example of a 'bad' pattern.

The Printed Pattern Database therefore provides an automatically labeled set of training data for use by supervised machine learning algorithms.

Moreover, new SEM images that are continuously being captured by the fab are also being added to the Printed Pattern Database. This dynamic environment allows the machine learning system to learn continuously and therefore improve its prediction accuracy. As the accuracy of the machine improves over time, the system moves closer to an expert system.

Benefits:

PCML builds a machine learning model from the data contained in the Printed Pattern Database and makes pattern risk predictions on nearly all of the patterns contained in the much larger Design Decomposition Database. These predicted scores are expected to be more reliable that purely statistical or geometrical signatures.

PCML builds a machine learning model from the data contained in the Printed Pattern Database and makes pattern risk predictions on nearly all of the patterns contained in the much larger Design Decomposition Database. These predicted scores are expected to be more reliable that purely statistical or geometrical signatures.

Technical Requirements

The minimum system requirements are listed below:

Memory and hard drive requirements can vary substantially from customer to customer. Customers who expect to store large quantities of images on the server should allocate appropriate hard drive capacity. Customers who expect to process large numbers of images should allocate additional physical memory. Anchor Semiconductor will help each customer with the appropriate sizing of their hardware.

- Linux 2.6 or later, 64-bit, x86 based processor.

- 16 or more physical cores.

- 128 GB or more physical memory.

- 2 TB or more available hard drive capacity.

Memory and hard drive requirements can vary substantially from customer to customer. Customers who expect to store large quantities of images on the server should allocate appropriate hard drive capacity. Customers who expect to process large numbers of images should allocate additional physical memory. Anchor Semiconductor will help each customer with the appropriate sizing of their hardware.