ADD: Advanced Defect Discovery

Advanced Defect Discovery is a workflow for generating defect sample plans for SEM Review that takes into account optical patch images, machine learning, and optionally the PCYM ranked database.

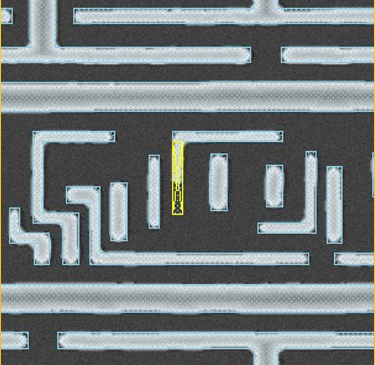

Review SEMs have been used for decades to compensate for the lack of resolution on optical inspection tools. Optical inspectors scan the wafer for defects, but their patch images are too pixelated and cannot be used to determine the type of each defect. A clear and detailed image of the defect is necessary to determine its type, its shape, its causal mechanism, and its impact to yield (killer versus non-killer).

Because of the relatively slow throughput of Review SEM tools, it is necessary to sample a subset of the defects that were detected by the optical inspector. If a poor subset is sampled, little if anything is learned. Fabs generally expect the sampled subset to (a) contain as many known defects of interest (DOI) as possible while also (b) discovering new defect types. It may seem straightforward to generate a sample plan that addresses both needs, but these are in fact competing requirements. If the sample plan is biased too much around (a), it will lose its ability to discover new defect types (b), and vice-versa.

Review SEMs have been used for decades to compensate for the lack of resolution on optical inspection tools. Optical inspectors scan the wafer for defects, but their patch images are too pixelated and cannot be used to determine the type of each defect. A clear and detailed image of the defect is necessary to determine its type, its shape, its causal mechanism, and its impact to yield (killer versus non-killer).

Because of the relatively slow throughput of Review SEM tools, it is necessary to sample a subset of the defects that were detected by the optical inspector. If a poor subset is sampled, little if anything is learned. Fabs generally expect the sampled subset to (a) contain as many known defects of interest (DOI) as possible while also (b) discovering new defect types. It may seem straightforward to generate a sample plan that addresses both needs, but these are in fact competing requirements. If the sample plan is biased too much around (a), it will lose its ability to discover new defect types (b), and vice-versa.

Advanced Defect Discovery

Given a budget of N sample points for SEM review, Advanced Defect Discovery applies machine learning techniques to generate a balanced sample plan while providing users the ability to bias the algorithm a little in either direction. Balancing the sample plan means choosing defects from the original population whose backgrounds are similar to known high-risk patterns (to increase cap rate of known DOI) while also choosing defects whose backgrounds are dissimilar to known good and bad patterns (to improve the chances of discovering new defect types).

This sampling methodology would not be possible without the Printed Pattern Database (known good and bad patterns), the Design Decomposition Database (collection of all patterns), and Machine Learning.

This sampling methodology would not be possible without the Printed Pattern Database (known good and bad patterns), the Design Decomposition Database (collection of all patterns), and Machine Learning.

Benefits:

ADD uses all available information from each wafer inspection (KLARF and patch images) and applies its own image processing and machine learning algorithms to generate an effective sample plan for SEM Review.

ADD uses all available information from each wafer inspection (KLARF and patch images) and applies its own image processing and machine learning algorithms to generate an effective sample plan for SEM Review.

Technical Requirements

The minimum system requirements are listed below:

Memory and hard drive requirements can vary substantially from customer to customer. Customers who expect to store large quantities of images on the server should allocate appropriate hard drive capacity. Customers who expect to process large numbers of images should allocate additional physical memory. Anchor Semiconductor will help each customer with the appropriate sizing of their hardware.

- Linux 2.6 or later, 64-bit, x86 based processor.

- 16 or more physical cores.

- 128 GB or more physical memory.

- 2 TB or more available hard drive capacity.

Memory and hard drive requirements can vary substantially from customer to customer. Customers who expect to store large quantities of images on the server should allocate appropriate hard drive capacity. Customers who expect to process large numbers of images should allocate additional physical memory. Anchor Semiconductor will help each customer with the appropriate sizing of their hardware.